The medical market turns to specialized suppliers in the investment casting technique to design alloy metal parts with impeccable integrity.

Moreover, to contribute to advancements in the surgical, orthopedic, and prosthetics markets, when the existing team possesses the necessary expertise, there is an opportunity to assist the client in creating unique prototypes.

Choosing a Trusted Partner in Lost Wax Investment Casting

Every new metal part of the medical industry places human innovation at the core. Therefore, it is crucial to select your business partner meticulously. The chosen precision foundry must:

- Implement an impeccable and unwavering process.

- Possess state-of-the-art equipment with regular maintenance plans.

- Have precise NDT (Non-Destructive Testing) throughout the manufacturing process.

- Be capable of supporting and advising you from the reception of engineering drawings to each stage of project progression.

Furthermore, your industry rightfully demands specific standards and compliances. Vestshell ensures their adherence and regular updates.

Certifications and Compliances for the Medical and Surgical Field

We understand what you need to assure your clients. All business partners in your cutting-edge industry should maintain up-to-date accreditation for the proper certifications and regulatory compliances.

Therefore, renewing ISO 9001:2015 certification periodically, the Export Administration Regulations (EAR) system and the controlled goods program is essential. We rigorously oversee this.

Key Alloys Used for Medical Parts

You guide us on the metals you wish to use for your projects, but typically, we use the following alloys in your sector:

- Austenitic stainless steels

- Martensitic stainless steels

- Precipitation-hardening steels

- Duplex steels

Air-melted alloys:

- Cobalt-based alloys

In the case of a different alloy in your project, we examine the possibility of substituting the metal with an equivalent (and sometimes more cost-effective) alternative. However, we ensure that it strictly adheres to the required standards.

3 Undeniable Advantages of Investment Casting

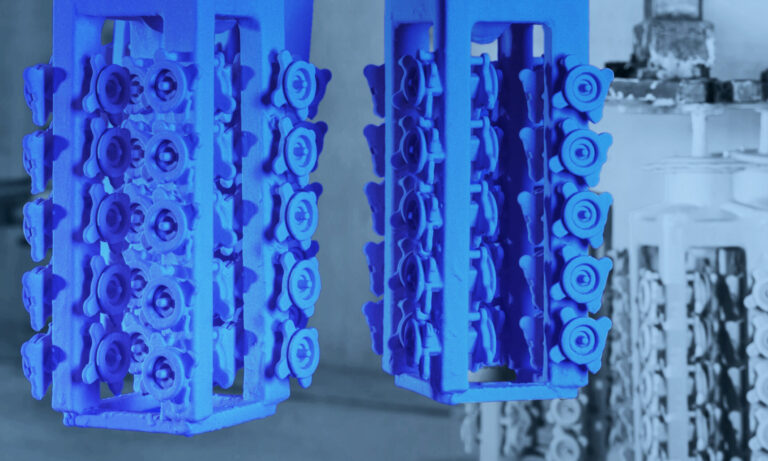

The investment casting manufacturing method offers numerous benefits for producing high-precision alloy metal parts.

- It provides excellent dimensional accuracy, enabling the creation of intricate parts with fine details.

- It allows for incredible design freedom, facilitating customized solutions that precisely meet your needs.

- This technique guarantees perfect reproducibility, ensuring consistent quality with every production run.

Whether your parts weigh less than an ounce or up to 150 pounds and occupy a volume of 0.250 to 24 cubic inches, they will always maintain the same quality and advantages.

Services Making a Real Difference in Cutting-Edge Industries

When submitting a new project, we understand that your time is valuable and deadlines are crucial. To optimize production times, choose a precision foundry that guarantees the details that make all the difference.

- A service for 3D design, modelling, and digitization.

- A compliance process including Non-Destructive Testing (NDT) such as dye penetrant inspection, magnetic particle inspection, radiography, and chemical analysis by spectrometry.

- Multiple heat treatment processes: vacuum, aging hardening, quenching and tempering, box annealing, vacuum carburizing.

- Equipment and solutions for treatment and automated processes, enhancing design and eliminating contamination and error risks.

- Chemical analysis by spectrometry.

- Advanced multidimensional straightening.

- Finish parts to a level requiring minimal to no machining.

Feasible Medical Parts

The lost wax investment casting technique yields incomparable results for a conscientious field like medicine. Consider this technique for all your specialized instruments and equipment. Of course, we present you with only a summary list:

- Surgical instruments

- Various prostheses or replacement components for joints

- Injury stabilization and rehabilitation devices

- Etc.

You can also submit your prototype ideas, and together, we will assess feasibility and production timelines.

Presenting Your Project to Vestshell

An honest and competent business partner should comprehensively analyze your project before accepting any new mandate, especially in such a specialized field. In this way, if alternative or more advantageous solutions arise, they should communicate them to you.

We commit to doing this at Vestshell with our 5-step feasibility analysis.

We are available to answer any questions you may have until you submit your request for a quote.

Similar articles

5 feasibility analysis criteria: investment cast part

The feasibility analysis to obtain a quote for an investment cast part covers the capacity, complexity, number of parts and lead time required.