Investment casting with automatic wax patterns offers cost savings due to minimal human intervention required once the setup is complete.

This is especially true when multi-cavity patterns are used. Although automatic patterns may cost more than manual ones, they can provide thousands of repeatable patterns at a lower cost, thereby justifying the investment.

Additionally, they can minimize the costs of maintenance, reworking, and replacement during future production runs.

The Precision Investment Casting Process

Step 1: Mold Design

The wax model used in investment casting is designed based on the specifications of the final metal part. It serves as a replica and template for the mold, and its accuracy is crucial since it will be reflected in the casting.

Step 2: Wax Injection

The wax is heated until it becomes liquid, and then it is injected under pressure into the mold of the desired shape. This process ensures that all the details and cavities of the mold are precisely filled with wax.

After being injected into the mold, the wax is left to cool and harden, taking the shape of the mold..

Once the wax has cooled and hardened, it is removed from the mold. This creates the wax pattern, which will serve as the template for creating the ceramic mold.

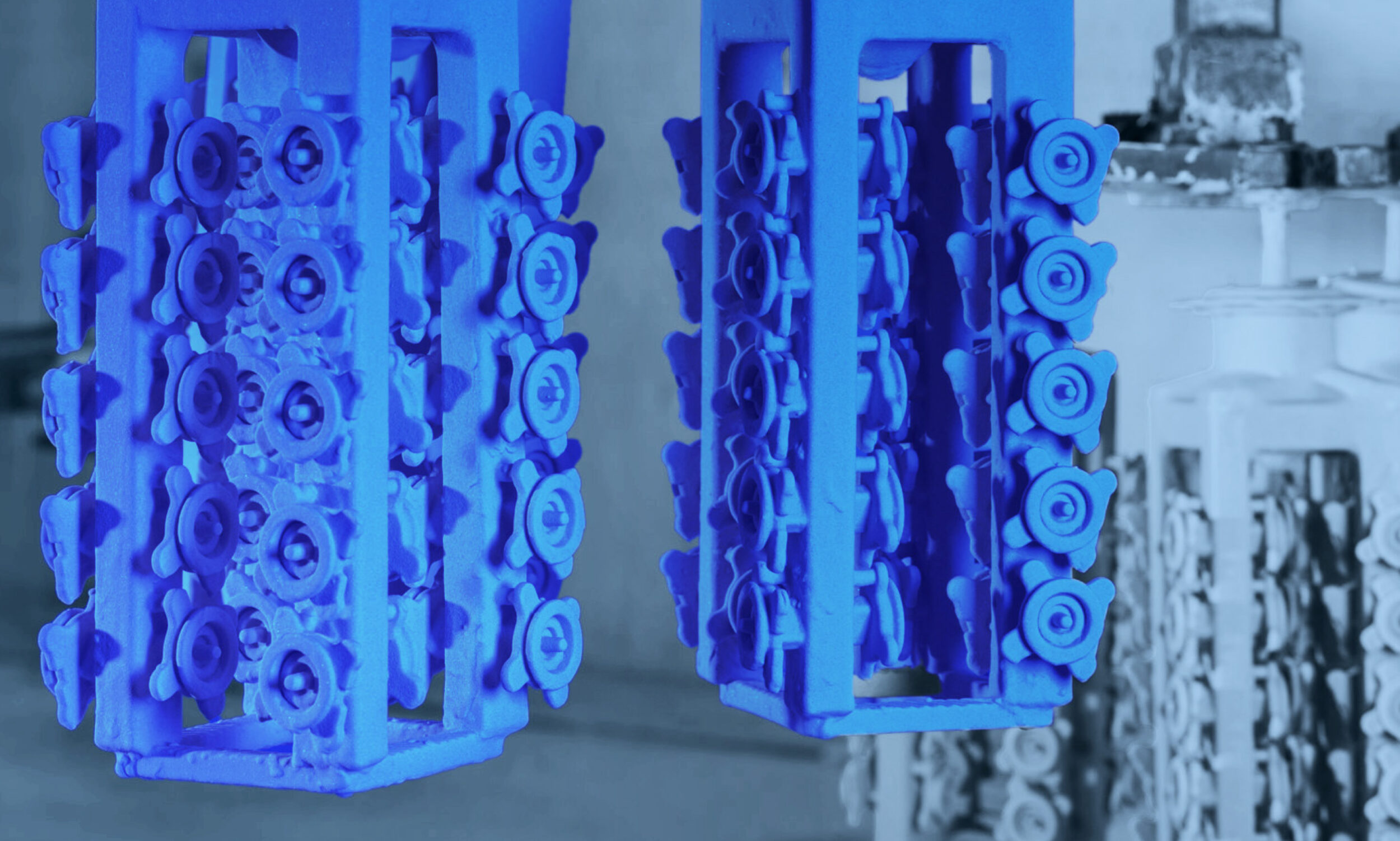

Step 3: Assembly Tree

If the final piece requires multiple parts, the individual wax models are assembled to form a complete model of the final piece.

Step 4: Shell Making

The wax pattern is then dipped in a refractory material (usually a ceramic slurry) to create a solid coating around the wax pattern. This step is repeated several times to build a strong mold shell.

The mold is heated to harden the refractory lining, creating a strong, heat-resistant mold.

Step 5: Dewax

The mold is heated to a high enough temperature to melt and remove the wax from the model, leaving a hollow cavity corresponding to the final metal part.

Step 6: Casting

The chosen metal is melted at high temperature, then poured into the ceramic mold to fill the cavity left by the wax.

Step 7: Knockout

The metal cools and solidifies in the ceramic mold. Once cooled, the ceramic mold is broken to reveal the cast metal part.

Step 8: Grinding

The cast metal part undergoes finishing operations, such as deburring, polishing and machining, to achieve the required tolerances and specifications.

Step 9: Inspection and Post Treatment

It is then subjected to quality control to ensure that it meets standards

Step 10: Finished Castings

The investment casting mold design process is essential to guarantee the precision and quality of the molded part.

Factors Affecting Accuracy in Precision Investment Castings

It’s important to consider several factors that can affect the accuracy of parts during wax injection in the lost wax casting process. Some of the main factors to keep in mind are:

Wax Quality: The quality of the wax used for the wax model can influence the accuracy. A high quality wax, free from impurities, is essential.

Wax Injection Process: The wax injection process must be carried out carefully to avoid air bubbles or deformation. Temperature and pressure parameters must be set correctly.

Mold Firing: Ceramic mold firing temperatures must be precisely controlled to avoid distortion or warping.

Cooling: Controlled cooling of the casting is essential to minimize distortion during curing.

Finishing: Finishing operations, such as deburring and machining, must be carried out precisely to achieve the required specifications.

Precision is a critical aspect of the wax casting process, and it requires attention to detail at every step, the use of high-quality materials and equipment, and rigorous quality control. By optimizing these factors, it is possible to produce high precision castings that meet the required specifications.

Applications and Industries for Precision Investment Castings

Investment casting is a versatile manufacturing process used in various industries to create a wide range of products and components. It is considered the best option for high-end industries, that require metal parts with exceptional quality and precision.

- automotive industry, improving engine efficiency, vehicle safety, and durability.

- aerospace sector, it is a mainstay in the production of engine parts, aerodynamic structures, and critical equipment that meet the highest quality standards.

- energy industry, it is central to the manufacturing of drilling equipment, turbines, power plant components, and many other essential applications.

Alloy steel investment casting, therefore, plays a vital role in these industries. It contributes to the reliability, performance, and safety of critical products and systems that move our world forward.

Investment casting is a manufacturing process that can create both parts with thin walls, intricate details, and high complexity.

Choosing a Precision Casting Foundry

Choosing the right investment casting foundry is crucial to ensure the quality and precision of the metal parts manufactured.

Before selecting a foundry, it’s essential to clearly identify your needs. This includes determining the type of metal parts required, their specifications, tolerances, materials, quantities, lead times, and budget.

Verifying the experience of each foundry is a crucial step in finding the right investment casting partner. One way to do this is by reviewing the foundry’s history, past accomplishments, and the industries it serves. A foundry that has experience in your field of application can often provide an advantage.

If possible, visiting the foundry’s facilities is an excellent way to assess its infrastructure, equipment, and level of technology. This can provide you with a better understanding of the foundry’s capabilities and help you determine whether they have modern, high-quality equipment for investment casting.

Make sure the foundry has a competent and experienced technical team, including qualified investment casting engineers and technicians.

Evaluate the foundry’s production capacity to ensure it can meet your needs in terms of quantity, delivery times, and flexibility.

Ultimately, the choice of investment casting foundry will depend on your specific needs and your confidence in its ability to meet those needs while meeting quality standards and delivery times.

Similar articles

Investment casting creates a prototype of flawless quality

Prototyping steel and other metal alloys parts using the investment casting process is a rigorous process for high-tech industries, such as the defence…