Advantages of Alloy Steel Investment Casting

To design metal alloy parts such as steel, aluminum, or other metals, an extremely rigorous investment casting technique is required.

This method is mostly used in industries that have exacting standards and require the most advanced quality standards. It is particularly suitable for the production of complex, one-off, or repeat parts.

Advantages of Alloy Steel Investment Casting

Alloy steel is an excellent choice for high-quality casting due to its numerous benefits. The advantages of alloy steel investment casting are undeniable.

- It guarantees exceptional quality, ensuring optimal performance under demanding conditions.

- The alloy steel casting process is extremely precise, ensuring that each part meets the highest specifications and providing unrivaled reliability.

- Alloy steel is an incredibly versatile material that offers a wide range of options to choose from, depending on your specific needs.

This makes it an excellent choice for investment casting as it provides uncompromising quality and exceptional performance in various applications.

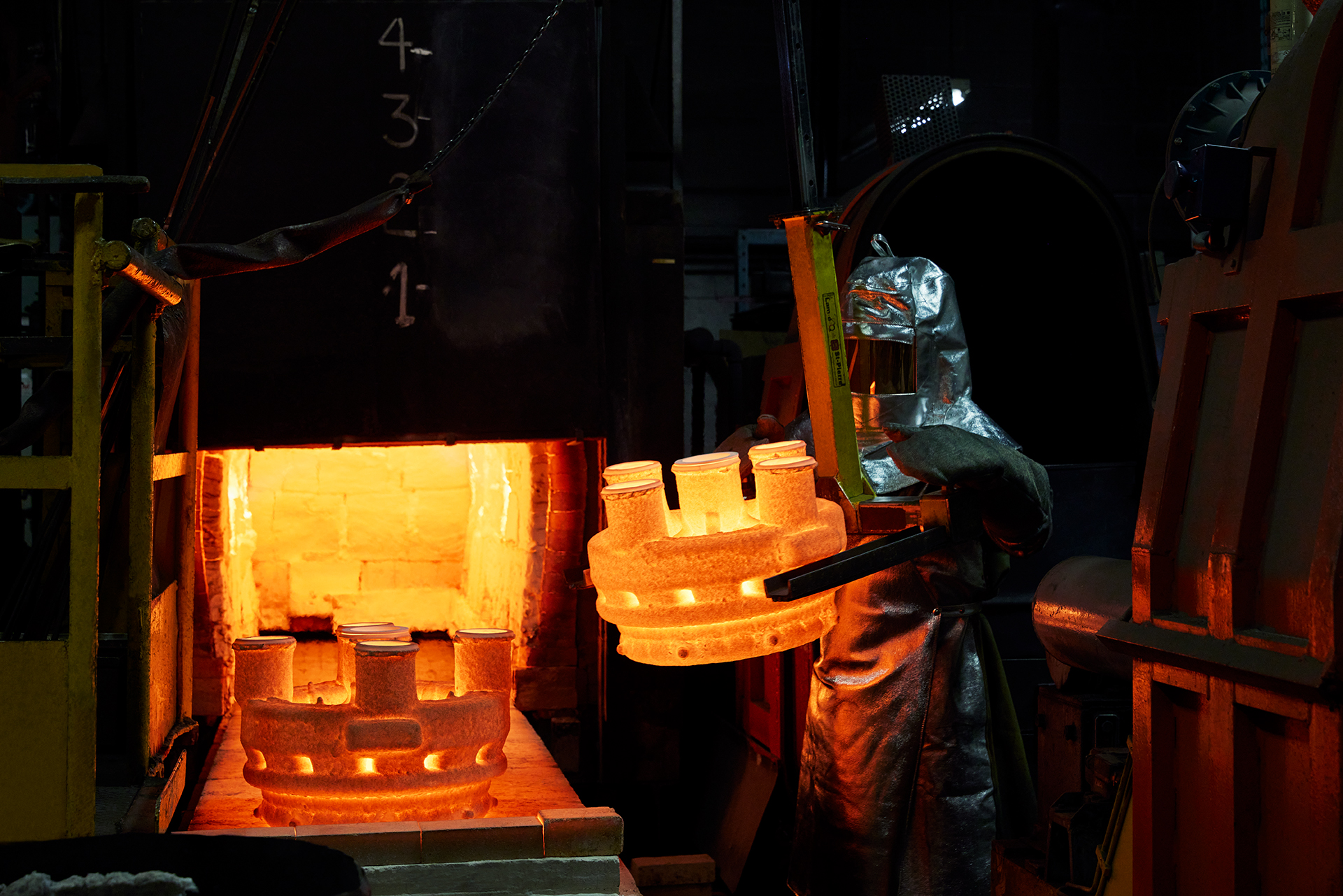

Alloy Steel Casting Process

Investment casting processes may vary between precision foundries. The process involves the expertise of several experienced specialists and specialized equipment to ensure maximum production speed and the highest level of quality required for specific steel, aluminum, or other metal alloy parts.

This technique guarantees that the parts are of the highest quality and comply in every respect to engineering drawings and the standards set by high-tech industries.

The steel casting process at Vestshell involves three essential elements that work together in perfect harmony.

Firstly, we conduct an in-depth exploration of the mechanical properties of alloy steel, enabling us to select the ideal composition to meet the unique requirements of each project.

Secondly, our state-of-the-art casting techniques, coupled with advanced equipment, ensure that each part is cast with pinpoint precision, resulting in impeccable outcomes.

Finally, meticulous finishing and heat treatment are the last steps in our process, delivering incomparable durability and strength.

Upon examining the process details closely, it becomes apparent how thoroughly the process is carried out to produce the kind of finished product demanded by high-tech industries. The parts conform to the required dimensions, angles, and other tolerances, which serves as evidence of the precision that investment casting entails.

Each casting has its own quality control methods; however, these are all carried out using a range of non-destructive tests (NDT).

All phases of the manufacturing process, includingNDT control, add up to a lengthy list of benefits:

- Lesser manufacturing costs

- Increased profitability

- Improved production and delivery time

- Elimination of irregularities and imperfections

- Quality control

- Contamination ans oxidation minimization

- Metal waste minimization

- Easier remanufacturing and repeatability

- Greater employee safety

At Vestshell, we are dedicated to technical mastery and excellence in every steel casting, ensuring our customers’ satisfaction and the exceptional quality of our products.

Applications of Alloy Steel Investment Casting

Alloy steel investment casting is an indispensable process that is extensively used in various major industries.

In the automotive industry, it plays a crucial role in manufacturing high-performance components, improving engine efficiency, vehicle safety, and durability.

In the aerospace sector, it is a mainstay in the production of engine parts, aerodynamic structures, and critical equipment that meet the highest quality standards.

In the energy industry, it is central to the manufacturing of drilling equipment, turbines, power plant components, and many other essential applications.

Alloy steel investment casting, therefore, plays a vital role in these industries. It contributes to the reliability, performance, and safety of critical products and systems that move our world forward.

Investment casting is a versatile manufacturing process that can create both parts with thin walls, intricate details, and high complexity.

This method can produce parts ranging from a few grams to several hundred kilograms. The possibilities are endless with investment casting.

Choosing the Right Alloy Steel for Casting

Selecting the appropriate alloy steel is a crucial step in the investment casting process.

Two main factors that influence this decision are:

- the level of mechanical strength required,

- the conditions under which the part will be utilized.

The mechanical strength depends on the role that the part plays, and whether it requires high tensile, compressive or flexural strength.

Moreover, the operational environment is also an important consideration, as it can lead to corrosion, wear, or other types of damage.

The widely used metal alloys can be divided into two categories: ferrous and non-ferrous.

Ferrous alloys include cast iron, carbon steel and low-alloy steel, austenitic stainless steel, martensitic stainless steel, and precipitation hardening steel.

Non-ferrous alloys are based on aluminum, titanium, copper, nickel, or cobalt.

When submitting a project to a precision foundry, it’s possible that the alloy you need may not be available. However, there are often equivalents that can be used. Specialists are available to offer advice and support for your needs, whether you require a single part to be machined, a new prototype to be developed, or a production run to be executed for the first time.

Capabilities and Services

At Vestshell, our ability to design and produce high quality alloy steel investment casting parts is unmatched. Our dedication to excellence is reflected in every aspect of our manufacturing process, from the careful selection of alloy steel to the final stage of heat treatment and finishing.

Our commitment to innovation and technical perfection allows us to meet the specific requirements of each project, whether in the automotive, aerospace, energy or other demanding fields.

By working with Vestshell, you benefit from the expertise of our qualified professionals, cutting-edge know-how and unwavering quality.

Our mission is to provide alloy steel investment casting solutions that exceed expectations, ensuring our customers obtain the highest quality parts for their critical applications.

To get all the information needed for creating your alloy steel castings, contact us at Vestshell.

Similar articles

5 feasibility analysis criteria: investment cast part

The feasibility analysis to obtain a quote for an investment cast part covers the capacity, complexity, number of parts and lead time required.