Precision foundry specializes in advanced industries: defence, medical, aerospace, nuclear, and high-end industrial sectors. Finding a reliable and skilled partner to design your metal alloy parts requires specific criteria. This is justified as your company operates in one of the five major advanced industries.

- Defence

- Medical

- Aerospace

- Nuclear

- High-end industrial

As a qualified precision foundry, it’s crucial for each project to go through the priority step of feasibility criteria. This ensures the quality of all our mandates, as they must adhere to the strictest industry standards.

In this article, we summarize what Vestshell can offer so you have the possibilities in mind for your sector. However, don’t limit yourself. Discussing a new project is always appropriate, as we specialize in various types of prototyping.

Lost Wax investment casting and the DefenCe Sector

The military and defence domain demands unwavering precision and reliability.

- For precise manufacturing, it’s essential to have technologies and equipment compliant with the current standards and requirements of the armed forces (naval, aerial, and land).

- Supporting technical assistance and co-engineering during the initial project phases ensure the success of steel parts and other metal alloy mandates. This guarantees the delivery of various military systems (precision navigation, etc.).

- The ability to develop high-precision castings ensures the proper functioning of weapon systems.

- Expertise in this field allows manufacturing parts for various military vehicles such as armoured vehicles, defence systems, fighters, aircraft, and helicopters.

- Assistance in the design of complex parts ensures the safety and reliability of military equipment.

Medical Industry and the Delicacy of Cast Metal Parts

The medical sector is an innovative nerve center. As a manufacturer and supplier of the highest quality and precision metal parts, flawless performance is necessary. Trust must be unwavering, integrity spotless, and the promise of perfection proven.

Investment casting is particularly suitable for alloy metal parts required in cosmetic and surgical sectors.

- Think of surgical and diagnostic medical tools requiring strict specifications and cosmetic aspects.

- Additionally, cast parts for the prosthetics market demand high criteria and characteristics regarding dimensional repeatability.

- The medical field also requires resistance tests for weight load or sterilization temperature.

- It is also possible to create specialized devices of complex design, such as a laryngoscope or others, for various technical environments: surgical, orthopedic, etc.

You need to submit a request for an existing item in the market or a new prototype. Together, we will explore the various avenues to actualize it.

Aerospace and Complex Metal Parts

The aerospace sector is one of the domains where accuracy and resilience are most crucial. There’s no margin for error, and we comprehend that.

We have the equipment and expertise to ensure compliance with your requirements. We prevent any traces of casting, oxidation, and contamination through our meticulous manufacturing process.

Furthermore, we’re mindful of the weight-sensitive conditions in the aerospace environment. Consequently, we produce thin-walled cast parts with strict Non-Destructive Testing (NDT) controls.

You’ve found the right partner if you wish to:

- Manufacture engines, landing gear, and wing flap controllers. We are well-versed in stringent alloy and design specifications.

- Create parts and components for all civil or military aircraft and drones.

- Seek technical assistance for designing, co-engineering, or producing unique or repeatable complex prototypes.

Request a quote for your project. Naturally, any classified and urgent mandate is treated as a priority and in a confidential manner.

Nuclear Industry and Demanding Precision Cast Parts

If you’re part of the nuclear industry, you understand how rigour and performance are standard vocabulary terms. They are for Vestshell as well.

We’ve been in this business long enough and have designed a sufficient number of parts, including components for the CANDU reactor, to understand their importance.

The role of your precision foundry partner is to consistently provide you with certified cast parts that meet the stringent standards of the nuclear industry in terms of reliability and performance.

You should also be accompanied by a team of experts who combine their skills and knowledge with yours to optimize the initial idea and plan, creating an unstoppable final piece.

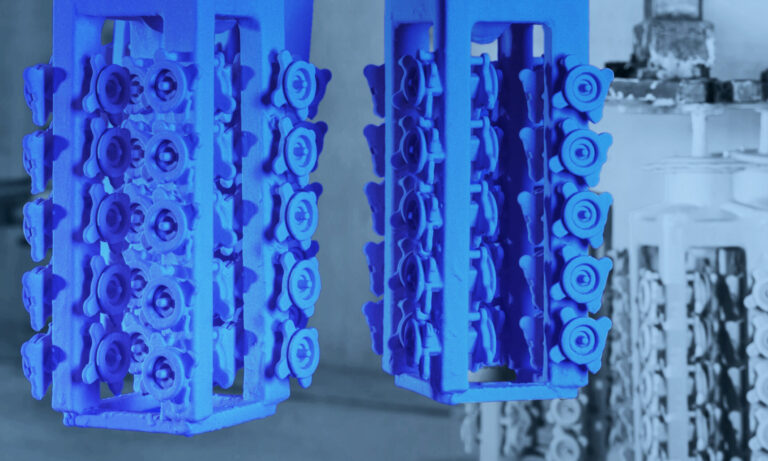

- Take a tour of the factory to ensure that rapid prototyping technology and equipment are in place to create wax, S.L.A., and polycarbonate models.

- Ensure the process is done through direct vacuum pouring under an atmosphere for minimal contamination.

- Benefit from personalized guidance by experts who have an eye for detecting possible improvements from the project’s inception phase.

- Ensure the manufacturer has solid experience with highly complex parts related to nuclear equipment requiring high safety standards.

- Validate compliance with industry quality and traceability requirements.

The nuclear industry must be prepared for any danger, starting right from manufacturing more advanced equipment components. Request a quote today from a company that fully understands your challenges.

Durability of Lost-Wax Casting for High-End Industrial

Requests in the high-end industrial field vary greatly for precision foundries. Lost-wax casting is highly advantageous as this industry requires exceptional durability, and this metal casting method is most suitable.

It is used to:

- Optimize the quality of your finished products

- Increase your operational efficiency

- Discover economic and beneficial options

- Benefit from the most high-performing equipment in the market

- Set yourself apart advantageously from your competitors

- Differentiate yourself positively among your clientele

This is conveyed as follows:

- By designing cast replacement parts for your industrial equipment.

- Creating molds (unique or repeatable) using rapid prototyping and technical support.

- By manufacturing precision steel parts that consistently surpass your linear and geometric tolerance standards.

In conclusion, selecting the right lost-wax casting partner demands certainty. Ask questions, read testimonials, and seek recommendations.

Your mandates are of paramount importance. Therefore, the precision foundry you choose must be qualified and impeccable.

Does Vestshell make this claim? With 60 years in business and countless loyal clients, we believe we have this legitimacy.

Similar articles

The difference between investment casting and sand casting

Should you choose investment casting or sand casting? It depends on the size of the part, metal used, complexity, quantity and delivery time.